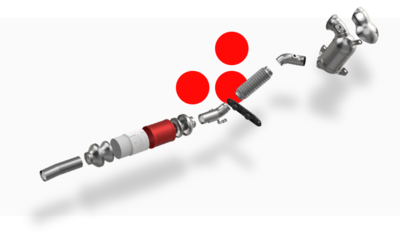

Emission control systems

With its highly efficient emission control systems, BOSAL makes an active contribution to environmentally compatible mobility worldwide.

Features

- All emission control systems are individually type-approved

- All BOSAL Aftermarket manufacturing is ISO/TS 16949 accredited

- All products are based on the original OEM design for a guaranteed perfect fit

- All exhausts are made from aluminized or stainless steel

- No welds inside the silencer

- A wide range of half-shell products

- A wide range of mounting parts to support the correct fitment of the exhaust system

- Easily accessible and user-friendly e-catalog

- Development cycles of 8 weeks ensuring pro-active and fast response when required

- Insider market knowledge that benefits the customer

OEM

BOSAL Powertrain manufactures fully integrated emission control systems that meet future demands for near-zero emissions, in close collaboration with many of the established Original Equipment Manufacturers (OEMs).

Discover Powertrain OEM

BOSAL offers the full emission control system combined with industry leading innovation.

OES

Original Equipment Supplier (OES) spare parts are the same as OEM spare parts in terms of authenticity and function. BOSAL manufactures these parts with exactly the same specifications as OEMs, with similar precision and detail. No compromises on quality.

Discover Powertrain OES

Spare parts equal to OEM parts in terms of authenticity and function.

Aftermarket

The company’s R&D facilities and OEM pedigree ensure innovative product solutions and strict testing programs to guarantee the quality, durability, and an ideal accuracy of fit. BOSAL offers the widest assortment of replacement exhausts to the global Aftermarket.

Discover Powertrain Aftermarket

Our R&D facilities and OEM pedigree ensure innovative and durable product solutions.