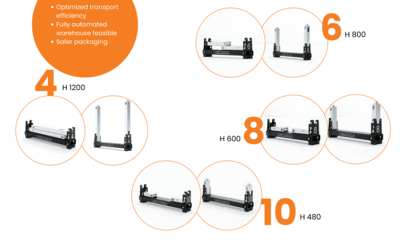

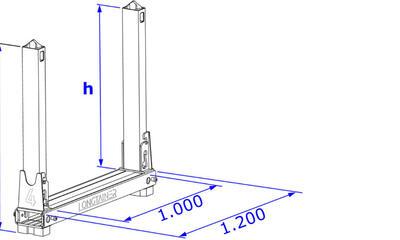

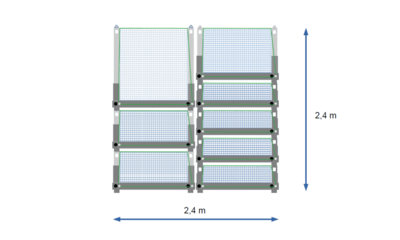

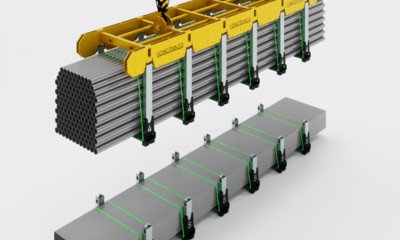

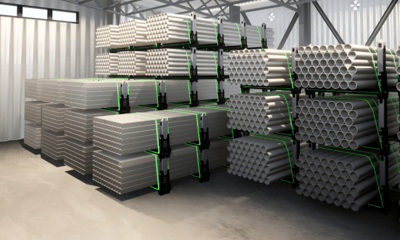

LONGTAINER is a new concept for packing, handling, storing and transporting of long products such tubes, profiles, bars, beams, and more, regardless of material. It provides safer packaging and allows fully automated warehouses.

LONGTAINER for sustainable packing stacking

To avoid poor stability of the shape of a bundle or damage of the products after several handlings during packing and transport, LONGTAINER is created to solve these issues. It also allows to save time, prevent intensive labor, and enables an automation that will optimize the production output.